Systems

Use the complete range of PLAST-CONTROL solutions and benefit from the quality of a German brand!

Special solutions

Vacuum supply, coupling detection and real-time transparency - special solutions from PLAST-CONTROL.

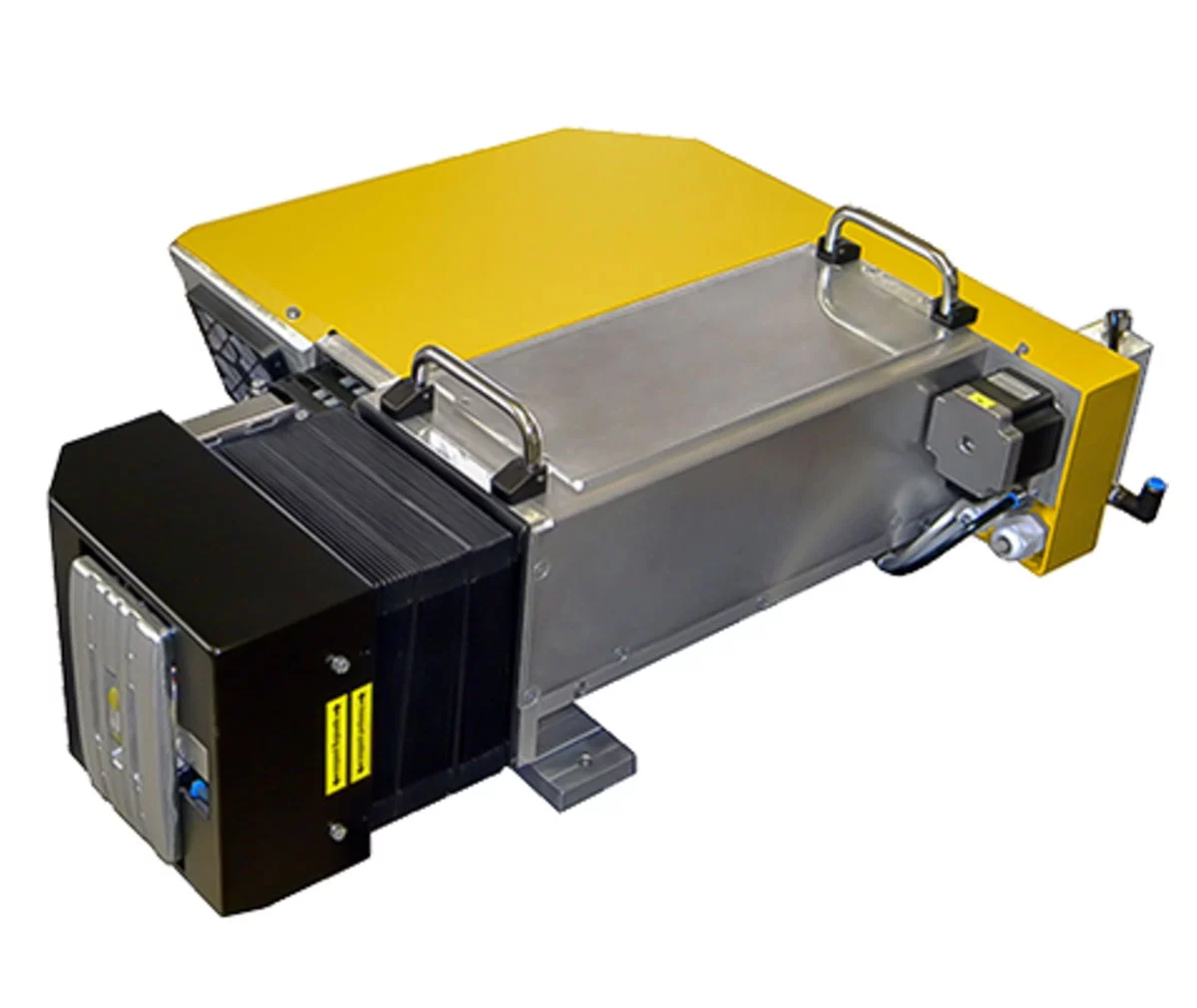

PRO-GRAV

Gravimetric extruder control and continuous feeding of all components for up to 7 components per extruder

PRO-CLEAN & DRAIN

Integrated solution for a clean gravimetric metering process and a fully automatic drain process for less material loss during job changes

C HEAD

The easy and precise film tolerance measurement for fast and effective measurement directly at the film bubble

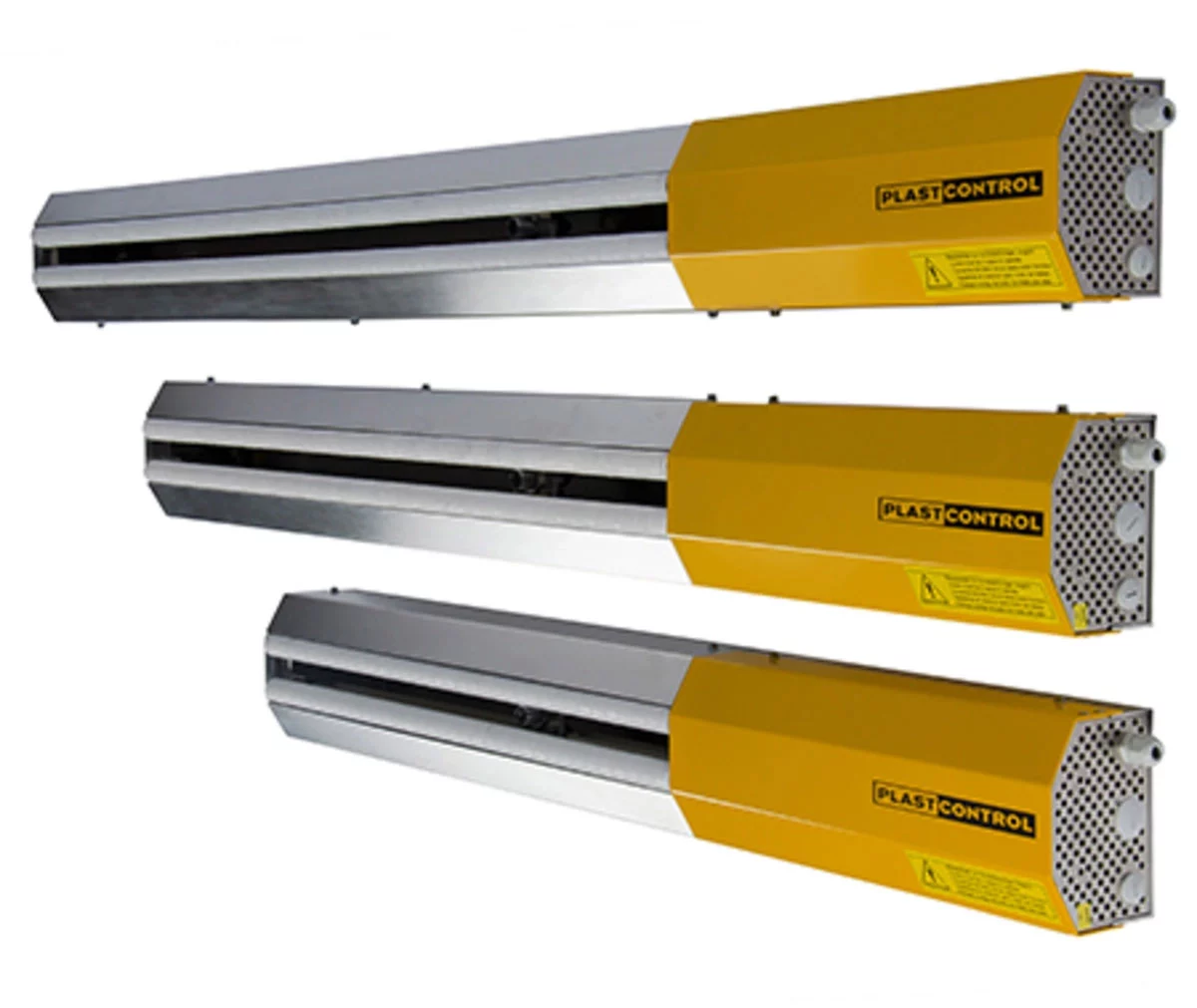

C-SCAN

Measurement of barrier films without radioactive measuring equipment on the film laid flat. 100% precise due to intelligent measuring software

PRO-WIDE

For films with side gussets, a width measurement can possibly be carried out via the ultrasonic sensors of the IBC. For films without side gussets, a separate width measurement is required.

PRO-CON

Modern, highly efficient air volume profile control. Fastest control results without additional energy input into the film.

PRO-CON-DUO II

Driving mode "long neck" as accessory for PRO-CON cooling rings to improve the film properties and increase the output rate

PRO-CON FLEX

The new automatic high-performance cooling ring allows significantly faster and more precise control of the cross-profile tolerances of the film

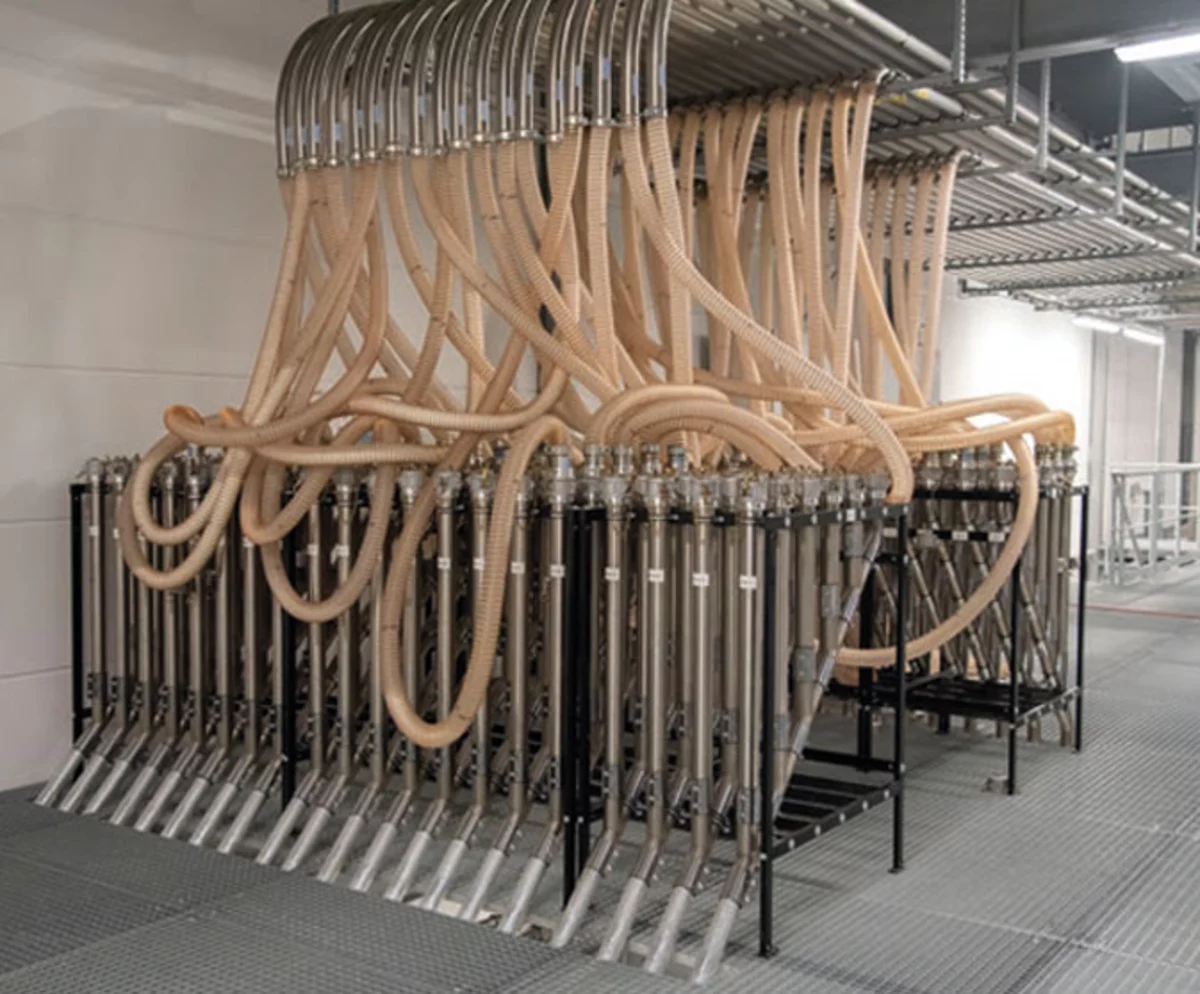

Central vacuum

More and more extrusion plants are centralizing the vacuum generation needed to convey raw materials from the silos to the machines.

PIPE-IDENT

Coupling detection PIPE-IDENT: Faulty coupling of pipelines is made largely impossible with PIPEIDENT.

PCH-E

Dust and impurities in the material cause problems in the extrusion process time and again. There are many solutions for this!

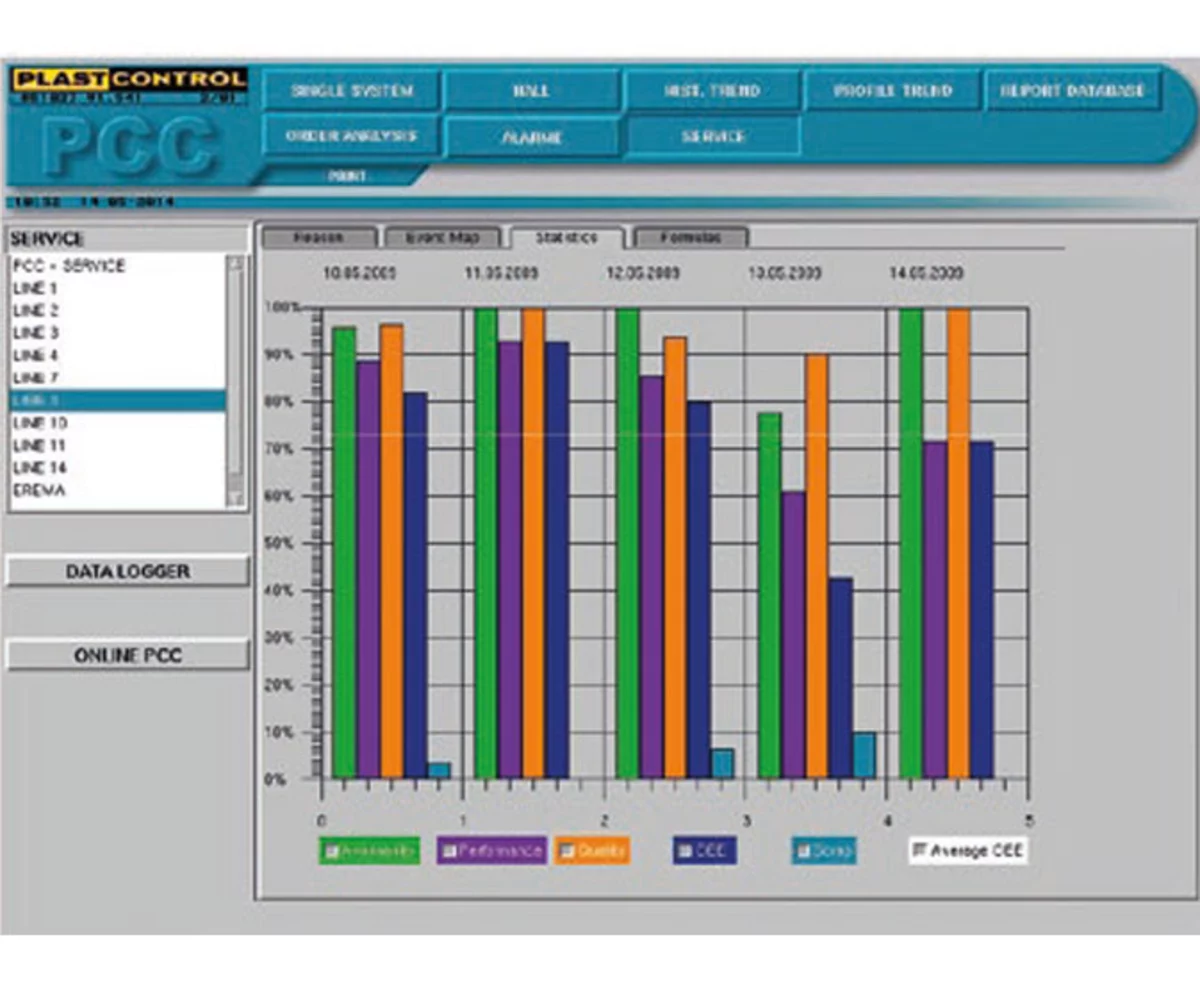

PCC

The plant-wide networking of all extrusion lines with PCC creates a previously unimaginable transparency of all actual processes in production - in real time!

PRO-SONIC

PRO-SONIC can be implemented in any PLAST-CONTROL computer. Three ultrasonic sensors are used for non-contact measurement.

PRO-CAGE

The PRO-CAGE calibration basket is an extremely important component for the producible quality of a film.

PRO-LAB

The PRO-LAB II is equipped with a probe for absolute measurement of foil profiles according to the standards DIN 533370/ ISO 4593/ASTM-D 6988-08.

PLAST-CONTROL is directly on site worldwide. Through our network of branches on all five continents, we have the experts on site and can be with you quickly if there is ever a "burning" matter.

We help install your chosen products on the blown film line, commission it together with you and only leave when the process is running stably and reliably.

Career at PLAST-CONTROL

Unfortunately, we do not have any vacancies at the moment, but we would be pleased if you would like to send us an unsolicited application! We will contact you as soon as we have a suitable offer for you. To apply, please use our email address: bewerbung@plastcontrol.de.

In your cover letter, please be specific about the areas you are interested in and your areas of specialization.