PRO-GRAV

The basis of extrusion line automation has been gravimetric extruder control for over 35 years.

The principle of "Loss-in-Weight" guarantees a throughput determination accurate to the percentage, independent of the bulk density. Especially for co-extrusion lines, no other control principle for layer thickness control is conceivable.

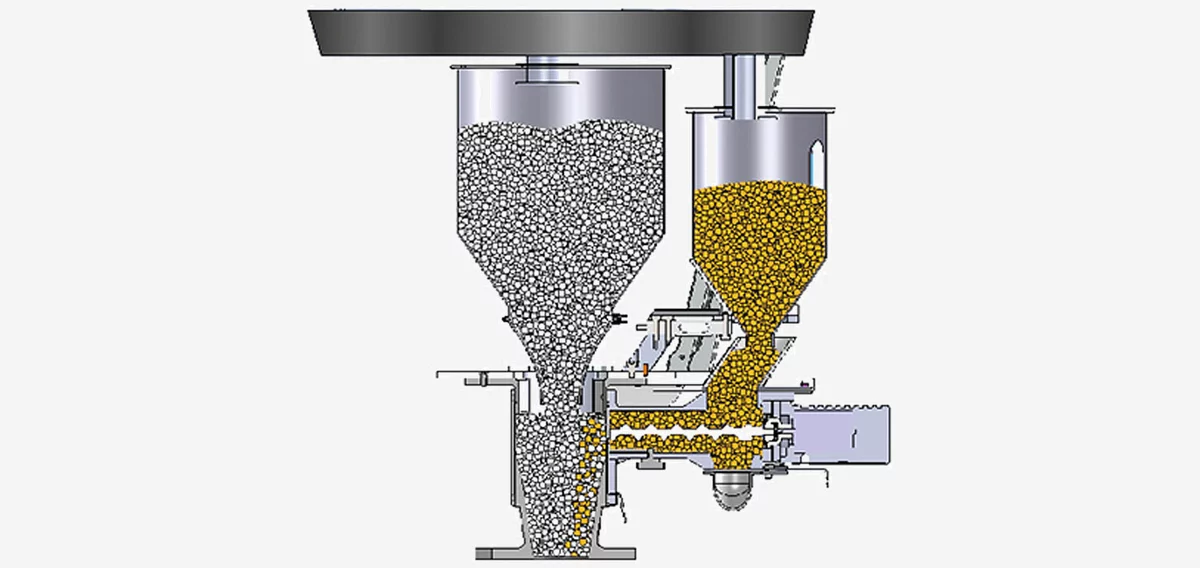

The modular design of PLAST-CONTROL makes it possible to connect up to six gravimetric feeders per extruder. The recipe-accurate metering of expensive additives and masterbatches takes place directly above the extruder feed. Segregation is thus impossible.

All feeders are of course controlled synchronously with the extruders to ensure correct mixing at all times.

Precise throughput determination is guaranteed by the loss-in-weight principle, regardless of the bulk density. Especially for co-extrusion lines, no other control principle for layer thickness control is conceivable. The control concept can be used for all continuous extrusion processes. A gravimetrically weighed hopper with a shut-off unit and a PC system are required. In co-extrusion lines, the layer thicknesses are controlled by adjusting the individual extruder throughputs, taking into account the setpoint specification. If the production level is increased by changing the haul-off speed, all extruders are synchronized and the product specifications are maintained even during the changeover phase. Taking into account the setpoint specification, the systems are able to control the running meter weights with the accuracy of ± 0.1% of the mean value. Regardless of whether the melt filter of an extruder is dirty during the night shift or whether a heating tape fails - the system detects the deviation from the setpoint, readjusts accordingly, and high-quality film continues to be produced. Experience shows that in practice up to 4% of raw material can be saved; ROI is usually achieved after 6 to 12 months.

Your advantage:

- Raw material savings

- no dependence on bulk density

- fast changeover times for job changes

- constant, consistent product quality

- simple setpoint control

- customer-specific solutions

- robust, durable design

- easy cleaning due to removable hoppers

- fast ROI

Your advantages of the PRO-GRAV

-

no dependence on bulk density

-

fast changeover times for job changes

-

robust design

-

exact metering, smallest quantity metering

-

simple setpoint control

-

customer specific solutions

-

up to 7 materials per extruder

-

no metering screw change necessary

-

easy cleaning due to removable hoppers

You have questions about the product?

Please feel free to contact us!

Tel: +49 2191 9 480 0

E-Mail: information(at)plastcontrol.de