PRO-VAC

The vacuum pump and high-performance dust separation.

Dust and all impurities in the material cause problems in the extrusion process time and again. Especially long suction lengths from the outer silos to the machine with many deflections generate abrasion, which should be filtered as far as possible. There are many solutions to these problems - just ask our engineers.

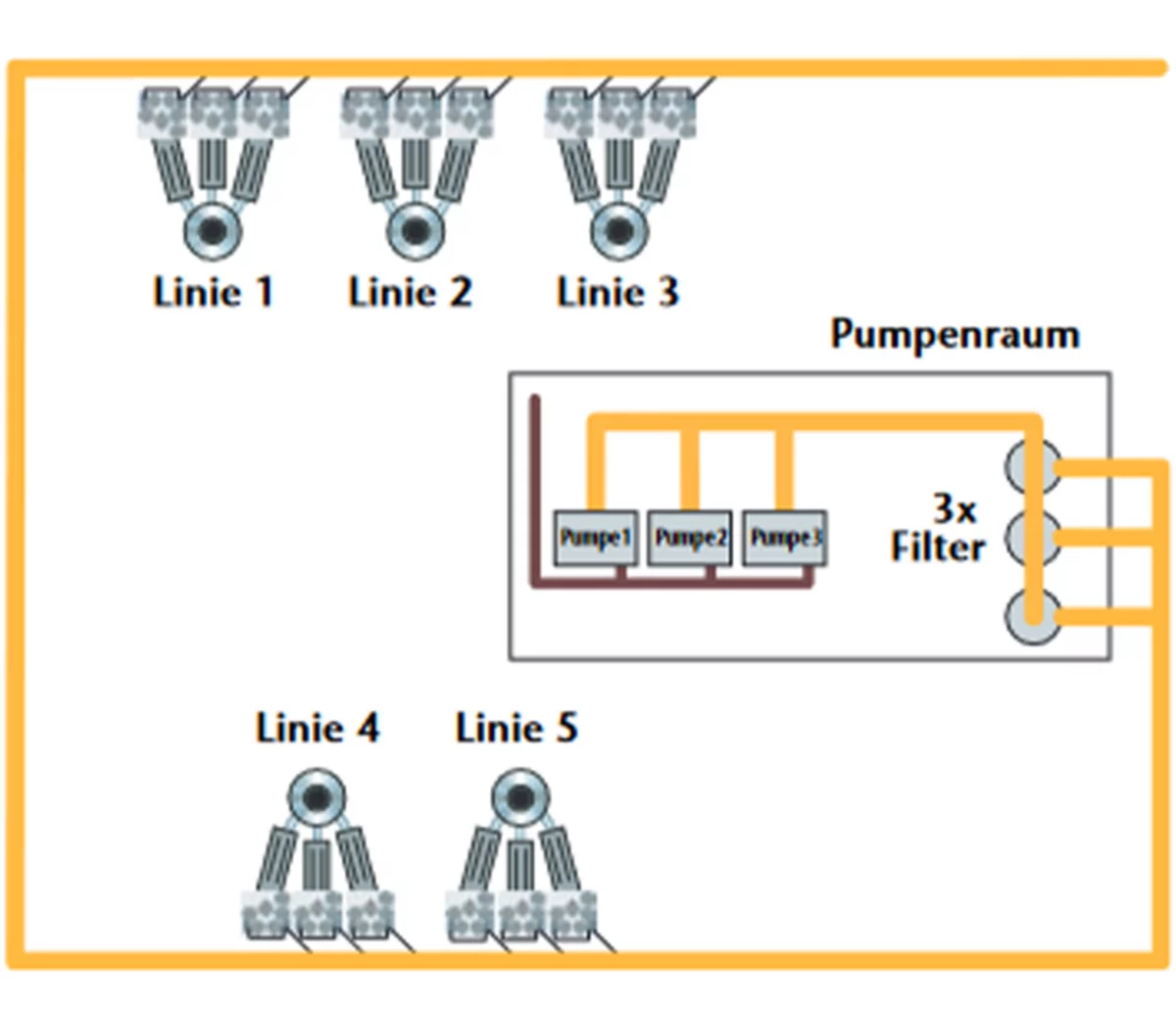

More and more extrusion plants are centralizing vacuum generation. Advantages such as energy efficiency, workplace noise protection and significantly increased performance at lower investment costs are just a few reasons. Availability is increased and maintenance is reduced.

Our engineers will select the optimum vacuum pump for you and your application. These can be conventional side channel blowers, claw pumps or Roots pumps. In our pilot plant, problematic materials can be vacuumed in pipes of Ø 38/50/70 mm (15'' / 19,7'' / 27,5'') over 130 m horizontal (426 ft) and 14 m (46 ft) vertical length.

For this purpose, several powerful vacuum pumps and corresponding prefilters are installed in a closed room. The entire production hall is supplied with vacuum via a central pipeline. In addition to the diverse hardware solutions for vacuum conveying, PLAST-CONTROL offers a variety of intelligent software solutions around this topic.

For example, Material Minimizing Control (MMC) was developed to minimize raw material losses due to changeovers and material changes. This program ensures that the storage bins are already completely empty during a changeover

and that there is only a small amount of material left in the weighing hopper.

You have questions about the product?

Please feel free to contact us!

Tel: +49 2191 9 480 0

E-Mail: information(at)plastcontrol.de